-

Are you facing problems with manpower shortage and low production?

-

Are you trying to cut down the increasing manpower costing?

-

Would you like to convert your 40/50 kg bags to 1000kg bags as done by major FMCG?

-

Are you trying to resolve issues related to weight inaccuracy/hygiene/human errors?

Features

-

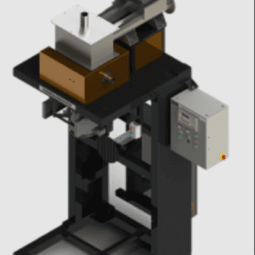

Bag clamp system-To avoid Leakage at mouth of the bag

-

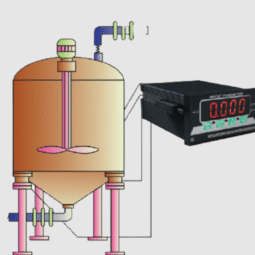

Weighing system-For achieving accuracy in weighing

-

Dust collection provision-For collecting dusts during filling process

-

Air purging system-For expanding bag to its full size

-

Vibrating system-Moves bag up and down to create more space and proper shape of bag

-

Display-6 Digit Led Display

-

Calibration-Digital

-

Programmable-Membrane Keyboard

-

Resolution-1 In 10,000

-

Accuracy- 0.5%

-

Speed- From 2 Min(Depending On Material Flow)

Built with a robust structure and precision weighing controls, it supports a wide range of free-flowing and semi-free-flowing materials such as grains, powders, fertilizers, minerals, and chemicals. Its automated filling mechanism reduces spillage, improves productivity, and maintains packing accuracy even in demanding industrial environments.

Ideal for large manufacturing units, processing plants, warehouses, and logistics facilities, this jumbo bag filling machine is a dependable solution for businesses looking to streamline bulk packaging and increase operational efficiency.

Choosing the Right Weighing System for Your Facility

When optimizing bulk material handling, weighing accuracy plays a major role in maintaining consistency across every stage of operations. If your facility uses multiple weighing systems such as platform scales, table-top scales, or industrial weighing machines understanding how each one contributes to productivity can help streamline your entire process.

To learn more about selecting the right weighing scale systems for your business, you can explore our detailed guides

Reviews

There are no reviews yet.