Fully Automated Unmanned Weighbridge Software – 24/7 Operation Without Manual Intervention

Revolutionize your weighing operations with our completely unmanned weighbridge software that enables 24/7 truck scale operations without any human supervision. Leveraging advanced RFID, automatic number plate recognition (ANPR), and self-service kiosk technology, this system eliminates labor costs while ensuring 99.9% accuracy and complete operational transparency.

Core Automation Features

🤖 Complete Automation Stack

-

RFID Vehicle Identification: Automatic tag reading for authorized vehicles

-

ANPR Camera Systems: License plate recognition for unknown vehicles

-

Self-Service Kiosks: Driver-operated weighing terminals

-

Auto Ticket Printing: Instant digital and physical tickets

-

Barrier Gate Control: Fully automated entry and exit systems

⏰ 24/7 Operation Benefits

-

Zero Labor Costs: Operates continuously without operators

-

Increased Throughput: Handle 3x more vehicles daily

-

No Shift Limitations: Round-the-clock weighing operations

-

Reduced Human Error: 99.9% weighing accuracy maintained

Technical Architecture

System Components

| Component | Function | Benefit |

|---|---|---|

| RFID Readers | Vehicle identification | Secure, instant vehicle recognition |

| ANPR Cameras | License plate capture | Backup identification method |

| Self-Service Kiosks | Driver interface | Simple operator-free weighing |

| Auto Barrier Gates | Traffic control | Automated vehicle flow management |

| Digital Signage | Instructions & status | Clear driver communication |

Software Specifications

| Feature | Specification | Impact |

|---|---|---|

| Uptime | 99.95% availability | Continuous operation |

| Security | AES-256 encryption | Tamper-proof records |

| Integration | REST API, Web Services | Seamless ERP connectivity |

| Backup | Real-time cloud sync | Zero data loss |

| Compliance | Legal for trade | Regulatory approval |

Weighing Process Automation

Fully Automated Weighing Cycle

def automated_weighing_process(): # Step 1: Vehicle approaches weighbridge vehicle_id = identify_vehicle() # RFID or ANPR # Step 2: Automatic data capture if vehicle_id in authorized_database: auto_open_gate() capture_gross_weight() display_instructions() else: direct_to_kiosk() driver_input_required() # Step 3: Processing auto_calculate_net_weight() generate_digital_ticket() update_central_database() auto_print_ticket_if_required() # Step 4: Exit auto_open_exit_gate() record_transaction_complete()

Vehicle Identification Methods

-

RFID Tags: Fastest method (2-3 seconds)

-

ANPR Cameras: Backup identification (5-8 seconds)

-

QR Code Scanning: Mobile-based entry

-

Manual Entry: Kiosk input for rare cases

Self-Service Kiosk System

Driver Interface Features

🚛 WELCOME TO UNMANNED WEIGHBRIDGE 1. SCAN RFID TAG → [Hold tag near reader] 2. OR ENTER VEHICLE NUMBER → [Use keypad] 3. SELECT MATERIAL TYPE → [Touchscreen] 4. FOLLOW VOICE INSTRUCTIONS → [Weighing process] 5. COLLECT TICKET → [Auto-print] 6. PROCEED TO LOAD/UNLOAD → [Gate opens automatically]

Kiosk Hardware Specifications

-

Weatherproof Enclosure: IP65 rated for outdoor use

-

Touchscreen Display: 15-21 inch industrial grade

-

RFID Reader: UHF/LF frequency support

-

Ticket Printer: Thermal auto-cutter

-

Surveillance Camera: Integrated for security

Security & Fraud Prevention

Advanced Security Measures

-

Weight Stabilization Control: Capture only stable readings

-

Time-stamped Photos: Vehicle images with each transaction

-

Digital Signature: Cryptographically signed weight records

-

Suspicious Activity Alerts: Real-time monitoring and alerts

Fraud Prevention Features

def detect_fraud_attempts(): check_weight_stability() # Prevent rocking vehicles verify_vehicle_consistency() # Match gross/tare profiles analyze_weighing_patterns() # Identify suspicious patterns cross_check_material_types() # Validate against history trigger_manual_review_if_suspicious()

Integration & Connectivity

Enterprise System Integration

Unmanned Weighbridge → Cloud Platform → Business Systems

↓ ↓ ↓

Vehicle Data → Real-time API → ERP

Weight Records → Data Stream → Accounting

Customer Portal → Web Services → CRM Supported Protocols & Interfaces

-

RFID Systems: EPC Gen2, ISO 18000-6C

-

Camera Integration: ONVIF compatible IP cameras

-

Scale Indicators: RS-232, Ethernet, USB

-

ERP Connectivity: SAP, Oracle, Custom APIs

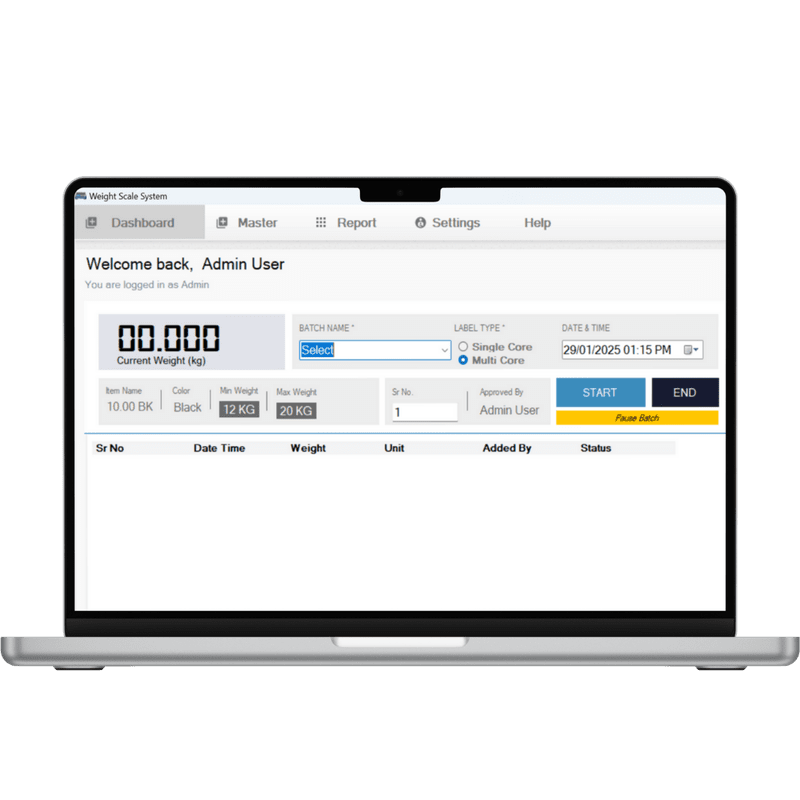

Real-Time Monitoring & Control

Central Control Room Dashboard

🏭 UNMANNED WEIGHBRIDGE NETWORK - LIVE ├── Site 1: 45 vehicles today | Current: 2 in queue ├── Site 2: 67 vehicles today | Current: System normal ├── Site 3: 23 vehicles today | Current: 1 at kiosk └── Network Status: All systems operational 🔔 RECENT ALERTS ├── Vehicle 1245: Weight fluctuation detected ├── Kiosk 3: Paper low warning ├── Camera 2: Requires cleaning └── All other systems: Normal 📊 PERFORMANCE METRICS ├── Avg Weigh Time: 2.5 minutes ├── Success Rate: 99.8% ├── Fraud Attempts: 0 today └── System Uptime: 100%

Remote Management Features

-

Live Camera Feeds: Real-time video monitoring

-

System Health Monitoring: Proactive maintenance alerts

-

Remote Configuration: Software updates and changes

-

Mobile App Access: Management from anywhere

Industry Applications

⛏️ Mining & Resources

-

24/7 Ore Haulage: Continuous mining operations

-

Contractor Management: Third-party vehicle tracking

-

Production Reporting: Real-time extraction data

-

Royalty Calculations: Automated government reporting

🚛 Logistics & Distribution

-

Fleet Management: Own and third-party vehicle tracking

-

Shipping Verification: Outbound load confirmation

-

Route Optimization: Load planning efficiency

-

Customer Billing: Automated invoice generation

♻️ Waste & Recycling

-

Inbound Weighing: Receiving facility automation

-

Material Grading: Automatic categorization

-

Supplier Payments: Weight-based calculations

-

Environmental Reporting: Compliance automation

🏗️ Construction & Aggregates

-

Material Dispatch: Automated outbound weighing

-

Project Tracking: Job-wise material allocation

-

Supplier Reconciliation: Automated receipt processing

-

Quality Control: Material specification compliance

Cost-Benefit Analysis

ROI Calculation Example

TRADITIONAL WEIGHBRIDGE (Manned) ├── Operators: 3 shifts × 1 operator = 3 personnel ├── Salary Cost: $150,000 annually ├── Operating Hours: 18 hours/day max ├── Human Errors: 2-5% inaccuracies └── Throughput: 80-100 vehicles/day UNMANNED WEIGHBRIDGE ├── Operators: 0 (fully automated) ├── Salary Cost: $0 ├── Operating Hours: 24/7 continuous ├── Accuracy: 99.9% automated precision └── Throughput: 200-300 vehicles/day ANNUAL SAVINGS: $150,000 + 200% capacity increase PAYBACK PERIOD: Typically 6-9 months

Implementation Timeline

Phased Deployment (4-6 Weeks)

Week 1-2: Infrastructure Setup

-

Hardware installation (RFID, cameras, kiosks)

-

Network connectivity establishment

-

Server and software installation

Week 3-4: System Configuration

-

Vehicle database setup

-

User and permission configuration

-

Integration with existing systems

-

Testing and validation

Week 5-6: Go-Live & Optimization

-

Driver training and communication

-

Live operation with monitoring

-

Performance optimization

-

Support handover

Choosing unmanned weighbridge automation is not about technology; it’s about trust, control, and measurable profit. It’s the future of industrial weighing and the smartest investment for any growing enterprise.

FAQ Section

Common Questions

Q: What happens if the system fails?

A: Multiple redundancy systems with manual override options. 24/7 support with rapid response.

Q: How do drivers learn to use the system?

A: Simple intuitive interface, on-screen instructions, multi-language support, and instructional videos.

Q: Can we integrate with our existing ERP?

A: Yes, we support all major ERP systems through REST APIs and standard interfaces.

Q: What about security and fraud prevention?

A: Multiple layers including vehicle profiling, weight pattern analysis, and real-time monitoring.

Q: How long does implementation take?

A: Typically 4-6 weeks from order to full operational deployment.