H1: Complete Weighing & Inventory Management System with Integrated Printing

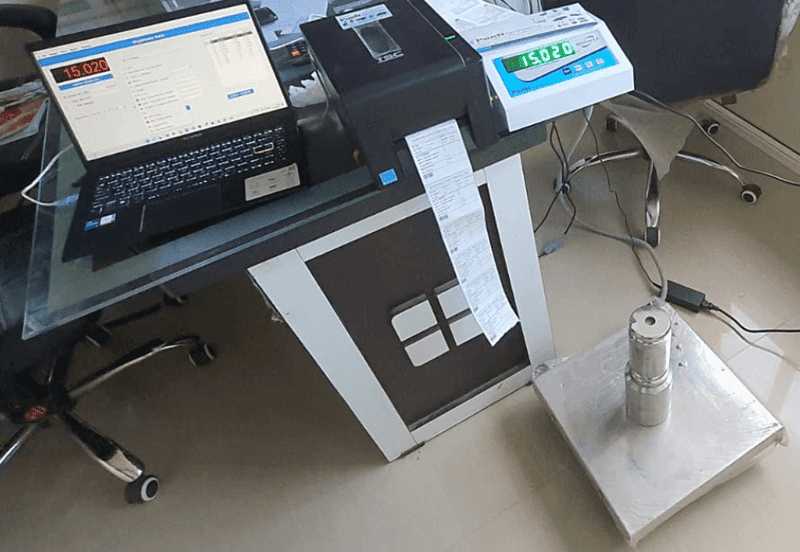

Transform your inventory operations with our all-in-one weighing scale system featuring built-in printer and comprehensive inventory management software. This intelligent solution combines precision weighing, automatic label printing, and real-time stock control in a single, seamless platform.

System Architecture

Integrated Hardware-Software Ecosystem

Weighing Scale → Inventory Software → Label Printer → Cloud Sync

↓ ↓ ↓ ↓

Weight Data → Stock Updates → Barcode Labels → Central Database Core System Components

-

High-Precision Weighing Scale (0.001g to 150kg capacities)

-

Integrated Thermal Label Printer

-

Inventory Management Software

-

Barcode Scanner Integration

-

Cloud-Based Data Synchronization

Key Features & Benefits

Inventory Management Capabilities

-

Real-Time Stock Tracking: Automatic inventory updates with each weighing

-

Multi-Location Support: Manage inventory across multiple warehouses

-

Automated Reordering: Low-stock alerts and purchase order generation

-

Inventory Valuation: Real-time stock value calculations (FIFO, LIFO, Average)

-

Stock Movement History: Complete audit trail of all transactions

Weighing & Printing Integration

-

Instant Label Generation: Print barcode labels immediately after weighing

-

Weight-Based Pricing: Automatic price calculation by weight

-

Batch Processing: Handle multiple items in single session

-

Tare Weight Automation: Automatic container weight deduction

Advanced Reporting & Analytics

-

Stock Level Reports: Current inventory status and trends

-

Movement Analysis: Fast/slow moving item identification

-

Waste Tracking: Shrinkage and loss monitoring

-

Profitability Analysis: Item-level margin calculations

Technical Specifications

Hardware Specifications

| Component | Specification |

|---|---|

| Weighing Capacity | 0.001g to 150kg (multiple models) |

| Weighing Accuracy | 0.001g to 1g (depending on capacity) |

| Printer Type | Industrial Thermal Transfer |

| Label Size | 30x20mm to 100x150mm |

| Barcode Types | QR, Code 128, EAN-13, Data Matrix |

| Connectivity | USB, Ethernet, Wi-Fi, Bluetooth |

| Display | 7-inch Touchscreen Interface |

Software Specifications

| Feature | Capability |

|---|---|

| Inventory Records | 100,000+ items capacity |

| User Accounts | Unlimited multi-user support |

| Data Storage | Local + Cloud synchronization |

| Report Generation | 50+ pre-built report templates |

| Integration API | REST API for ERP connectivity |

| Mobile Access | iOS/Android companion app |

Inventory Management Features

Core Inventory Functions

-- Inventory Database Structure ITEMS_MASTER { item_id, item_name, category, supplier, current_stock, min_stock, max_stock, cost_price, selling_price, weight_unit }

Stock Management Modules

-

Inventory Receiving: Goods-in weighing and recording

-

Stock Issuing: Material dispatch with weight verification

-

Stock Transfers: Inter-location movement tracking

-

Cycle Counting: Regular inventory verification

-

Returns Management: Reverse logistics handling

Advanced Inventory Features

-

Batch/Lot Tracking: Expiry date management

-

Serial Number Tracking: Individual item tracing

-

Multi-UOM Support: Pieces, kilograms, grams, pounds

-

Kit Management: Bundle and kit creation

Printing System Capabilities

Label Printing Features

-

Smart Label Templates: Customizable layout designer

-

Variable Data Printing: Weight, date, price, barcodes

-

Batch Label Printing: Multiple labels in single operation

-

Auto-Increment Serialization: Sequential numbering

-

Compliance Labels: Regulatory requirement formats

Document Printing

-

Weighing Tickets: Transaction documentation

-

Inventory Reports: Stock level summaries

-

Movement Reports: Receipts and issues documentation

-

Barcode Labels: Product identification labels

Workflow Automation

Goods Receiving Process

-

Weigh Incoming Goods → Automatic weight capture

-

Print Receiving Label → Barcode with weight data

-

Update Inventory → Real-time stock increase

-

Generate GRN → Goods Received Note creation

Sales/Dispatch Process

-

Weigh Items for Sale → Accurate weight measurement

-

Print Sales Label → Price and product information

-

Update Stock Levels → Automatic inventory reduction

-

Generate Invoice → Sales documentation

Inventory Counting Process

-

Weigh Current Stock → Physical count verification

-

Print Count Labels → Counting session identification

-

Reconcile variances → System vs physical comparison

-

Adjust Records → Approved stock adjustments

Integration Capabilities

Business System Connectivity

Weighing System → API Gateway → External Systems

↓

ERP, Accounting, E-commerce, WMS Supported Integrations

-

ERP Systems: SAP, Oracle, Microsoft Dynamics

-

Accounting Software: QuickBooks, Xero, Sage

-

E-commerce Platforms: Shopify, Magento, WooCommerce

-

Warehouse Management: Custom WMS integration

Industry Applications

Retail & Supermarkets

-

Fresh Produce Management: Weight-based pricing and labeling

-

Inventory Control: Real-time stock level monitoring

-

Price Optimization: Dynamic pricing based on weight and quality

Manufacturing & Production

-

Raw Material Management: Precise ingredient weighing

-

Work-in-Progress Tracking: Production stage weighing

-

Quality Control: Weight verification and compliance

Warehousing & Logistics

-

Shipping Weight Verification: Accurate freight calculations

-

Inventory Accuracy: Reduced stock discrepancies

-

Order Fulfillment: Efficient picking and packing

Pharmaceutical & Healthcare

-

Batch Tracking: Complete lot traceability

-

Compliance Documentation: Regulatory requirement meeting

-

Precision Formulation: Accurate ingredient weighing

Implementation Process

Phased Implementation

-

Assessment Phase (1 week): Requirements analysis

-

Installation Phase (2-3 days): Hardware and software setup

-

Data Migration (1-2 weeks): Existing inventory import

-

Training Phase (1 week): User training and acceptance

-

Go-Live & Support (Ongoing): Continuous optimization

System Requirements

-

Hardware: Standard PC or touchscreen terminal

-

Network: Stable internet for cloud features

-

Power: Standard electrical outlets

-

Space: Minimal footprint for scale and printer

Return on Investment

Quantifiable Benefits

-

Inventory Accuracy Improvement: 95-99% accuracy achievable

-

Labor Time Reduction: 60-70% faster weighing and labeling

-

Error Reduction: 90% decrease in weighing and recording errors

-

Stock Optimization: 20-30% reduction in excess inventory

Cost Savings

-

Reduced Shrinkage: Better inventory control reduces losses

-

Optimized Purchasing: Data-driven replenishment decisions

-

Labor Efficiency: Reduced manual data entry time

-

Improved Customer Service: Accurate stock availability information

Support & Maintenance

Comprehensive Support Package

-

24/7 Technical Support: Phone, email, and remote assistance

-

Regular Software Updates: Feature enhancements and security patches

-

Hardware Maintenance: Scale calibration and printer servicing

-

User Training Refreshers: Ongoing training sessions

Service Level Agreements

-

Platinum Support: 24/7 with 1-hour response time

-

Gold Support: Business hours with 4-hour response

-

Silver Support: Next-business-day response

A cheaper scale requiring expensive proprietary labels might cost more over three years than a pricier model using standard label rolls. Your weighing scale with a printer becomes a daily tool that affects productivity, accuracy, and customer experience.

Case Studies

Success Stories

-

Food Distributor: 99% inventory accuracy achieved

-

Manufacturing Plant: 65% reduction in weighing time

-

Retail Chain: 40% improvement in stock turnover

-

Warehouse Operator: 90% reduction in shipping errors

Working with a top weighing scale manufacturer in India not only brings peace of mind, it lets your business focus on the core work, leaving the measurement and compliance worries behind.

Reviews

There are no reviews yet.