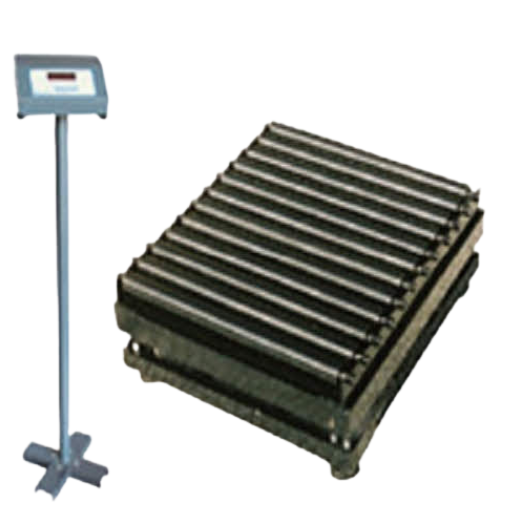

Roller Platform Weighing Scale

Weigh + Move — Without Lifting or Stopping Your Material Flow

A game-changing weighing solution for production lines, conveyor systems, and dispatch zones, where material is moved on rollers and must be weighed seamlessly during motion.

-

✔ Integrated roller conveyor + weighing platform

-

✔ Zero lifting — just roll, weigh & move

-

✔ Reduces manpower, time & material handling effort

-

✔ ERP / WMS integration for real-time dispatch data

-

✔ Supports line automation & zero bottlenecks

Where Roller Weighing is the Perfect Fit

Best for high-throughput industrial workflows:

-

Packaging & FMCG plants – carton/pallet weighing on line

-

Dispatch lines – weigh just before labeling and loading

-

Courier & logistics – fast parcel throughput

-

Chemical & pharma – drums, containers

-

Manufacturing with conveyor movement

-

E-commerce fulfillment centers

Optimized for loads that move continuously through conveyors + roller tables.

What Problems It Solves

If you are manually lifting items for weighing, you face:

❌ Slow operations + queue build-ups

❌ Operator fatigue & handling injuries

❌ Inaccurate weights due to shock loading

❌ Manual entry errors causing stock mismatch

With this solution:

✔ Material flows without break

✔ Throughput speeds up

✔ One-touch weighing ensures accuracy

✔ Digital traceability improves compliance

Built for Seamless Conveyor Integration

-

Modular inline installation on existing conveyor routes

-

Zero-transfer roller design for smooth movement

-

Vibration-isolated weighing base for stable results

-

Adjustable roller height for perfect alignment

-

Side guards for carton/drum stability

This keeps weighing fast, ergonomic & scalable.

Platform & Roller Design

Mechanical Structure

-

Heavy-duty MS fab structure

-

Galvanized / SS roller options

-

Low-noise & sealed bearings

-

Optional powered rollers for automatic transfer

Indicator & Controls

-

Bright LED/LCD display for long-distance visibility

-

Zero / Tare / Hold / Counting

-

Digital input/output for automation

Durability

-

Designed for continuous conveyor-line operations

-

IP-rated load cells for dust & moisture

Technical Specifications (Configurable)

| Specification | Options |

|---|---|

| Capacity | 50 kg – 3000 kg models |

| Roller Material | MS / SS / PVC rollers |

| Platform Length | Custom to conveyor width |

| Dimensions | Custom (width, height, pitch) |

| Load Cells | 1–4 high-accuracy, shock-resistant |

| Connectivity | RS-232 / USB / Ethernet / Wi-Fi |

| Mounting | Inline / on-ground / pit type |

| Printer Options | Label / barcode / slip printing |

| Compliance | Legal Metrology (where applicable) |

Each system is tailor-made to your conveyor line.

Software & Automation Add-ons

-

Automatic weighing + barcode label printing

-

Weight recording on PC / tablet

-

Direct sync with ERP / WMS / dispatch systems

-

Auto tare and container tracking

-

Integration with RFID, QR & vision systems

You get traceability of every single movement.

Why Choose Punit Instrument

-

30+ years experience in industrial weighing

-

Specialized in custom conveyor + weighing automation

-

Pan-India installation & service network

-

Quick spares availability for zero downtime

-

Strong domain knowledge of factory dispatch and audits

Weighing + Automation — designed to boost productivity.

When This Is the Right Choice

Choose this if…

✓ You want zero lifting of cartons/drums

✓ You want continuous movement on line

✓ You need speed + accuracy for high throughput

✓ You want to capture real-time data directly into systems

If batching, filling or static weighing is required —

a traditional platform scale may be better.

FAQs

Q. Can it weigh continuously in motion?

Yes — we provide both static & dynamic weighing versions.

Q. Can it match my existing conveyor height?

Yes — we precisely align it to your line level.

Q. Can forklifts or pallet trucks roll over it?

We build reinforcement as required, depending on model.

Q. Will it integrate with label printers & scanners?

Absolutely — one of our most common automation setups.

Reviews

There are no reviews yet.